SPIROL invented the Coiled Spring Pin and its production technology in 1948. Since that time, the Coiled Pin has proven to be the most versatile Spring Pin in the industry. Easily recognized by its unique 2 1/4 coil cross-section, Coiled Pins are self-retaining fasteners achieved by radial tension applied against the hole wall, and they are the only press-fit pins designed to remain flexible after installation. More than fasteners, SPIROL Coiled Pins are shock-absorbing elements that are integral, active components of a total assembly. Coiled Spring Pins are available in three duties, light duty, standard duty and heavy duty, to enable the designer to select the right combination of strength, flexibility and diameter to suit different host materials, strength requirements and loading types. SPIROL Coiled Pins typically offer the lowest installed cost in most applications.

Otherwise known as Spiral Pins, Coil Pins, Roll Pins or simply Spring Pins, SPIROL offers Coiled Spring Pins in both inch and metric sizes in a variety of materials and finishes from 0.8mm / .031” (1/32) in diameter up to 20mm / .750” (3/4) in diameter. Select from our expansive standard offering, or take advantage of our complimentary Application Engineering support and allow us to work with you to help determine the most appropriate Coiled Pin for your specific application and assembly needs!

If installation equipment is required, SPIROL also offers a standard comprehensive line of Pin Installation Equipment from manual to fully automatic modules, with or without out fixturing, to support your Coiled Pin assembly requirements.

heavy duty, to match the required strength and flexibility for each application. A pin too strong for the applied force will not flex and can cause damage to the hole. A pin too flexible could prematurely fatigue in the application. The Coiled Pin with the optimal combination of strength, flexibility and diameter will result in the prolonged useful life of an assembly. Generally speaking, light duty Coiled Pins are used in plastic and other soft, brittle or thin materials, standard duty Coiled Pins are used in mild steel and non-ferrous host materials, and heavy duty Coiled Spring Pins are used in hardened materials where space prohibits the use of a larger diameter standard duty pin.SPIROL also offers a selection of Coiled Pins designed for common application-specific requirements such as cosmetic cases, key fobs, head rests, transmissions, card locks and ejector clips. If one of SPIROL’s standard Coiled Spring Pins does not meet your needs, our Application Engineers will work with you to design a custom Coiled Pin to meet your unique requirements.Select from the options below for more specificity about SPIROL’s Coiled Pin offering or contact us for complimentary technical support!

M Standard

H Heavy

L Light

B High Carbon Steel

W Alloy Steel

D Stainless Steel, Austenitic (Nickel)

C Stainless Steel, Martensitic (Chrome)

UNS G10700 / G10740

C67S (1.1231) / C75S (1.1248)

UNS G61500

51CrV4 (1.8159)

UNS S30200 / S30400

18-8 (1.4310)

HV 420 – 545

HV 420 – 545

Work Hardened

M Standard

H HeavyK Plain, Oiled

T Electroplated, Zinc

L Light

TO ORDER: Product Code / Diameter / Length / Duty / Material / Finish

EXAMPLE: CLDP 8 X 32 MBK

Only Coiled Pins utilize the coiled spring concept; a recognized superior pin design. This imparts to SPIROL Coiled Spring Pins unique features not found in other Spring Pins or Solid Pins. More than fasteners, SPIROL Coiled Pins are shock-absorbing elements that are integral, active components of a total assembly. There are other pinning methods, but when the total assembly’s manufacturing cost, quality and useful life are important, the pin of choice is the SPIROL Coiled Spring Pin.

SPIROL provides general design guidelines and complimentary Application Engineering support to help you design your assembly to achieve the desired form, fit and function for the life of the product.

Take advantage of SPIROL’s complimentary Application Engineering support to help you select the proper Coiled Pin to meet both your application and assembly requirements.

CUSTOMER CHALLENGE:

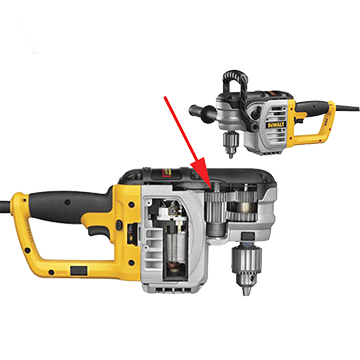

A leading automotive manufacturer approached SPIROL for a cost-effective solution to precision align the lower engine block to the primary engine block.

SPIROL SOLUTION:

SPIROL SOLUTION:

CUSTOMER CHALLENGE:

SPIROL SOLUTION:

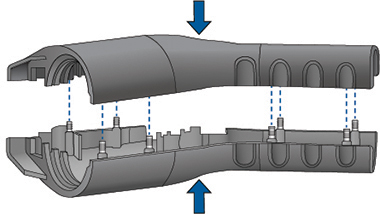

SPIROL Engineering recommended replacing the screws with Press-N-Lok™ Pins that were specifically designed as retention pins for plastic enclosures.

Press-N-Lok™ Pins have barbs that provide high retention in plastics. As the pins are pressed into the plastic, the barbs displace the plastic host material. After installation, the plastic backfills behind the barbs to lock the pins in place.

The assembly time for the Press-N-Lok™ Pins was much quicker and the assembly equipment costs was lower compared to the screws previously used.

SPIROL’s Press-N-Lok Pins simplified the assembly process, and eliminated scrap events associated with the installation of the screws.

CUSTOMER CHALLENGE:

A manufacturer of electric vehicle charging handles had been experiencing high scrap rates during assembly due to screws stripping the plastic host. They wanted to replace the screws with permanent, tamper resistant fasteners that also supported lean manufacturing.

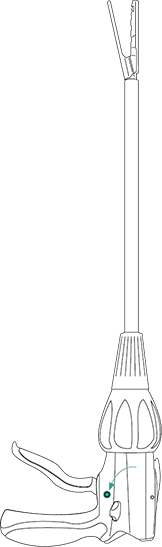

CUSTOMER CHALLENGE:

A leading medical device manufacturer approached SPIROL for assistance in designing a self-retaining trigger pin that eliminated cracking of the plastic yoke within the surgical stapler. 1

SPIROL SOLUTION:

CUSTOMER CHALLENGE:

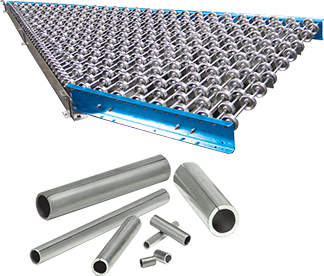

The lead engineer at an industrial conveyor manufacturing company approached SPIROL to help resolve an issue caused by low quality plastic tubing used to separate skate wheel rollers from each other and from the conveyor walls.

SPIROL SOLUTION: